Digital signage for inventory management in manufacturing warehouses has become an essential tool for streamlining operations. These warehouses, which form the backbone of many industries by serving as hubs for production, storage, and distribution, often deal with complex and challenging inventory management tasks.

In this article, we will delve into how digital signage is revolutionizing inventory management in manufacturing warehouses and why it plays a pivotal role in enhancing efficiency.

Challenges in Inventory Management in Manufacturing Warehouses

a. Inventory Tracking and Visibility Issues

One of the most significant challenges in managing inventory is ensuring accurate tracking and visibility. Traditional methods often involve manual data entry, which can lead to errors, discrepancies, and delays in locating items within the warehouse.

b. Manual Data Entry and Recording Errors

Human errors are unavoidable when relying on digital signage entry for inventory management. Misplaced decimal points or incorrect product codes can result in costly mistakes that disrupt production schedules and customer deliveries.

c. Lack of Real-time Information

Timeliness is crucial in managing inventory effectively. Outdated information can lead to overstocking or understocking of products, both of which can impact a company’s bottom line and customer satisfaction.

d. Space Limitations and Organization Challenges

Limited warehouse space and poor organization can make it difficult to optimize inventory placement. This can result in inefficient material handling and longer lead times.

Benefits of Implementing Digital Signage for Inventory Management

a. Improved Inventory Accuracy

Digital signage provides real-time updates on inventory levels and locations, reducing the risk of errors associated with manual data entry. This accuracy is crucial for just-in-time manufacturing and minimizing excess stock.

b. Real-time Data Updates

With digital signage, information about inventory levels, product movements, and order status is updated instantly. This real-time visibility enables warehouse managers to make informed decisions quickly.

c. Enhanced Visibility and Control

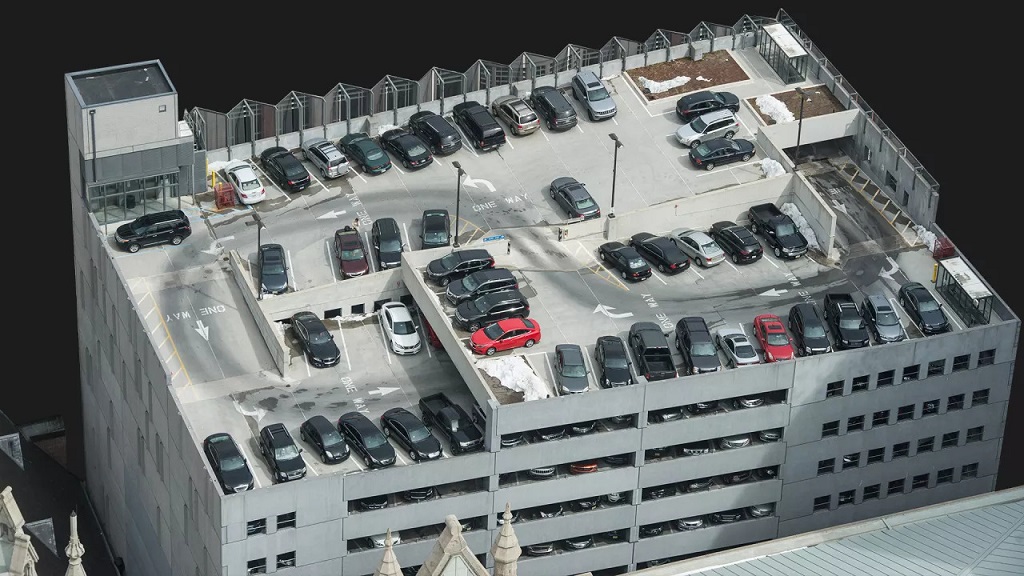

Large LED displays strategically placed throughout the warehouse can provide a bird’s-eye view of the inventory. This increased visibility allows for better control over stock levels, reducing the likelihood of stockouts or overstocking.

d. Reduced Operational Costs

Improved inventory management through digital signage can lead to cost savings. By optimizing stock levels, reducing errors, and streamlining processes, warehouses can operate more efficiently and reduce operational expenses.

Components of a Digital Signage System for Inventory Management

To implement digital signage effectively in inventory management, several components need to be considered:

a. Hardware Requirements

This includes the digital display screens, media players, and any sensors or scanners needed for data input. The choice of hardware depends on the warehouse’s specific requirements and budget.

b. Software Solutions

Warehouse management software (WMS) and digital signage software are essential for content creation, management, and scheduling. These solutions should be capable of integrating with existing inventory systems.

c. Integration with Existing Systems

To ensure seamless operations, the digital signage system must integrate with the warehouse’s existing software and hardware infrastructure, such as inventory management systems and barcode scanners.

d. Content Creation and Management

Designing and updating content for digital signage is an ongoing process. It involves creating visually engaging displays that convey critical information to warehouse staff.

Implementation Process

Implementing digital signage for inventory control in manufacturing warehouses involves several key steps:

a. Assessing Warehouse Needs and Goals

Start by understanding the specific inventory management challenges and goals of your warehouse. What information needs to be displayed, and where should digital signage be placed for maximum impact?

b. Selecting the Right Digital Signage Solution

Choose a digital signage solution that aligns with your warehouse’s requirements and budget. Consider factors such as hardware, software, scalability, and support.

c. Installation and Setup

Install digital displays in strategic locations within the warehouse, ensuring they are visible to employees and integrated with your inventory management systems.

d. Training and Onboarding

Train employees on how to use the digital signage system and ensure they understand its benefits in improving inventory management.

Best Practices for Digital Signage in Inventory Management

To maximize the effectiveness of digital signage in inventory management, consider these best practices:

a. Content Design and Layout Tips

Create visually appealing and easy-to-understand content. Use clear graphics, fonts, and colors to convey information quickly.

b. Maintenance and Troubleshooting

Establish a regular maintenance schedule to ensure displays are functioning correctly. Have a troubleshooting plan in place to address any technical issues promptly.

c. Security and Data Protection Considerations

Protect sensitive inventory data by implementing security measures and access controls for digital signage systems.

d. Employee Engagement Strategies

Encourage employee engagement with the digital signage system by soliciting feedback, promoting its benefits, and using it for employee recognition and communication.

Return on Investment (ROI) and Cost Analysis

It is crucial to assess the Return on Investment (ROI) connected with the use of digital signage for inventory control. Take into mind the following elements:

a. Costs

Include the costs of hardware, software, installation, training, and ongoing maintenance.

b. Benefits

Assess the benefits in terms of reduced errors, improved efficiency, and cost savings. Calculate how quickly the investment pays for itself.

c. Long-term Savings and Efficiency Gains

Consider the long-term savings and efficiency gains that come from improved inventory management, such as reduced carrying costs and increased customer satisfaction.

Conclusion

Digital signage for inventory management is transforming manufacturing warehouses, revolutionizing how they handle long-standing challenges and reaping numerous benefits. By improving accuracy, providing real-time data, enhancing visibility and control, and reducing operational costs, digital signage has become an essential tool for warehouse optimization, much like how it can help you organize a messy garage with efficiency and ease. As technology continues to advance, the role of digital signage in inventory management is poised to evolve even further, making it an exciting and indispensable investment for manufacturing warehouses seeking to remain competitive in the industry.