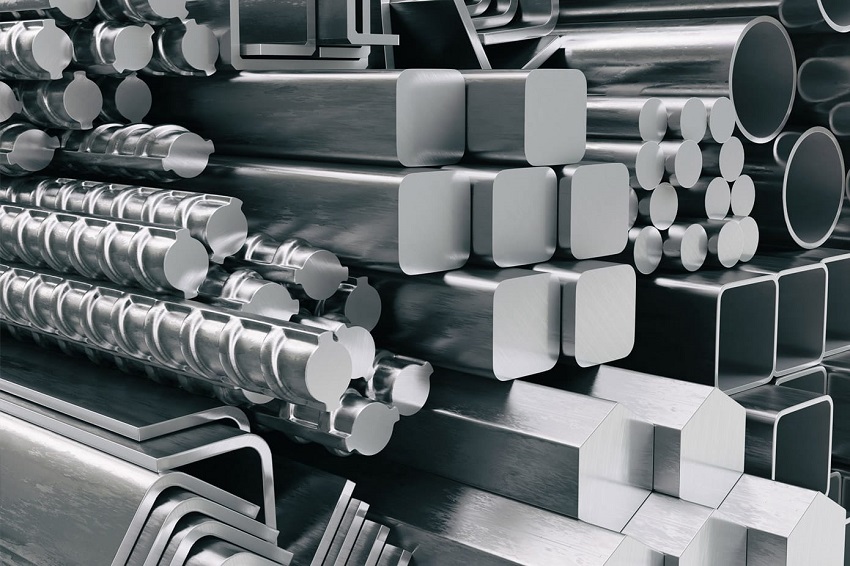

In today’s world of advanced technology and power tools, it may seem like cutting metal without them is impossible. However, there are various techniques and methods that can be employed to cut metal without relying on power tools. Whether you find yourself in a situation where power tools are not available or you simply prefer a more traditional approach, this article will explore some effective methods for cutting metal using alternative techniques. So, let’s dive in and discover how you can accomplish this task without the use of power tools.

The Basics of Hand Tools

When it comes to cutting metal, it’s important to have the right tools for the job. If you’re looking to cut a metal closet rod, there are a few methods you can use. Before getting started, make sure you have the basic hand tools needed for cutting metal, such as a hacksaw, snips, or a metal-cutting saw. With these tools, you can discover how to cut metal closet rod with ease and precision.The key hand tools for cutting metal include:

- Hacksaw: A hacksaw is a versatile cutting tool with a fine-toothed blade that can cut through various types of metal.

- Chisels: Chisels can be used to score and cut metal surfaces, especially softer metals like aluminum.

- Files: Metal files are abrasive tools that can shape and remove material from metal surfaces.

- Tin Snips: Tin snips are designed specifically for cutting thin sheet metal and are ideal for intricate cuts.

- Cold Chisels: Cold chisels are sturdy tools used for cutting through thicker pieces of metal.

Now that we have a good understanding of the basic tools, let’s explore some techniques for cutting metal without power tools.

Method 1: Hacksaw Technique

The hacksaw is one of the most common hand tools used for cutting metal. To cut metal using a hacksaw, follow these steps:

- Secure the metal piece: Clamp the metal piece firmly in a vise or use a workbench with clamps to ensure stability during cutting.

- Mark the cutting line: Use a marker or scribe to indicate the line you want to cut along. This will help guide your cutting action.

- Choose the right blade: Select a hacksaw blade with the appropriate tooth count for the type of metal you are cutting. Finer tooth blades are suitable for thinner metals, while coarser tooth blades work better for thicker metals.

- Position the blade: Insert the hacksaw blade into the frame and tighten it securely. The teeth of the blade should face forward.

- Start cutting: Apply gentle pressure and begin sawing back and forth along the marked line. Let the saw do the work, and avoid using excessive force, as it may break the blade or damage the metal.

- Maintain a steady pace: Keep a consistent sawing motion, adjusting the angle if necessary, until you have cut through the metal.

- Finishing touches: Use a file to smooth any rough edges left by the sawing process.

Method 2: Chisel and Hammer Technique

The chisel and hammer technique is suitable for cutting softer metals or making precise cuts. Follow these steps:

- Secure the metal: Similar to the hacksaw technique, ensure the metal piece is firmly held in place using a vise or clamps.

- Mark the cutting line: Clearly mark the line you want to cut along using a marker or scribe.

- Position the chisel: Place the chisel along the cutting line, ensuring it is perpendicular to the metal surface.

- Start hammering: With a hammer, strike the chisel’s handle to score the metal along the cutting line. Make sure to strike with controlledforce to avoid damaging the metal or injuring yourself.

- Repeat the process: Continue striking the chisel along the marked line, gradually increasing the depth of the cut. Take your time and make multiple passes if necessary.

- Break the metal: Once you’ve scored the metal deeply enough, you can use pliers or a vice grip to bend and break it along the scored line.

- Smooth the edges: Use a file or sandpaper to remove any sharp edges or burrs left by the cutting process.

Read More: How to bleed mountain bike brakes without a kit?

Method 3: Torch Cutting

Torch cutting involves the use of heat to melt or burn through metal. This method is best suited for thicker metals and should be performed with caution. Here’s how you can cut metal using a torch:

- Safety first: Ensure you are in a well-ventilated area and wearing appropriate safety gear, including goggles, gloves, and protective clothing.

- Prepare the work area: Clear any flammable materials from the vicinity and have a fire extinguisher nearby as a precaution.

- Choose the right torch: Select a torch suitable for metal cutting, such as an oxy-acetylene torch or a plasma cutter. Follow the manufacturer’s instructions for setup and operation.

- Mark the cutting line: Use a marker or scribe to indicate the line you want to cut along.

- Ignite the torch: Safely ignite the torch according to the manufacturer’s guidelines.

- Heat the metal: Direct the flame of the torch to the marked line and move it along the cutting path. Apply heat until the metal reaches its melting point or starts to burn.

- Assist the cutting process: As the metal heats up, use a separate tool like pliers or tongs to apply pressure and assist in breaking or separating the metal along the cutting line.

- Cool down and clean up: Allow the metal to cool down completely before handling it. Use a file or sandpaper to smooth any rough edges or burrs.

Conclusion

Cutting metal without power tools is indeed possible with the right techniques and tools at your disposal. Whether you opt for the hacksaw, chisel and hammer, or torch cutting method, each approach has its advantages and is suitable for different metal types and thicknesses. Remember to prioritize safety throughout the cutting process and take necessary precautions to avoid accidents or injuries. By mastering these alternative cutting methods, you can confidently tackle metal cutting tasks even without access to power tools. So, go ahead and give it a try! With practice, you’ll become proficient in the art of cutting metal by hand.